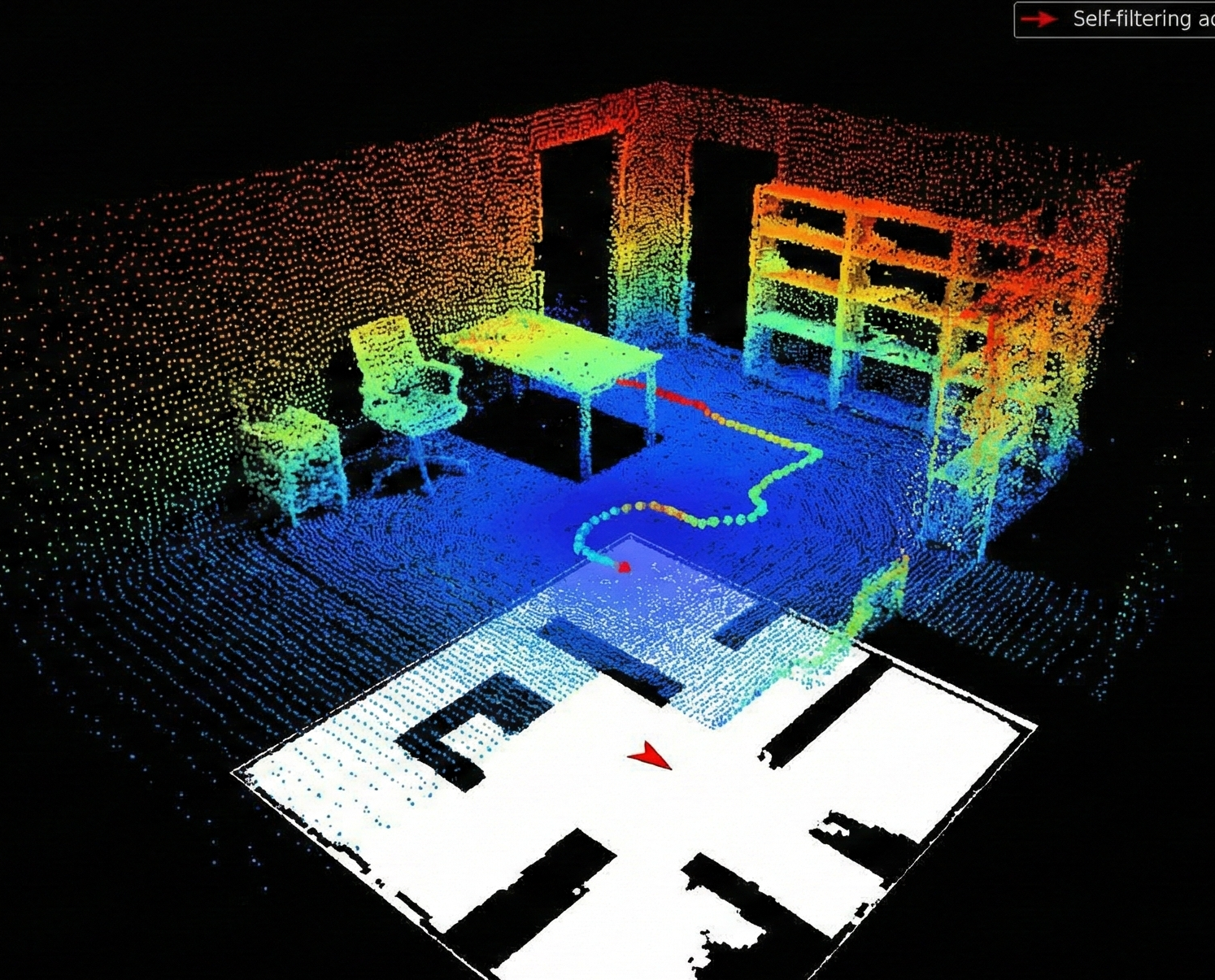

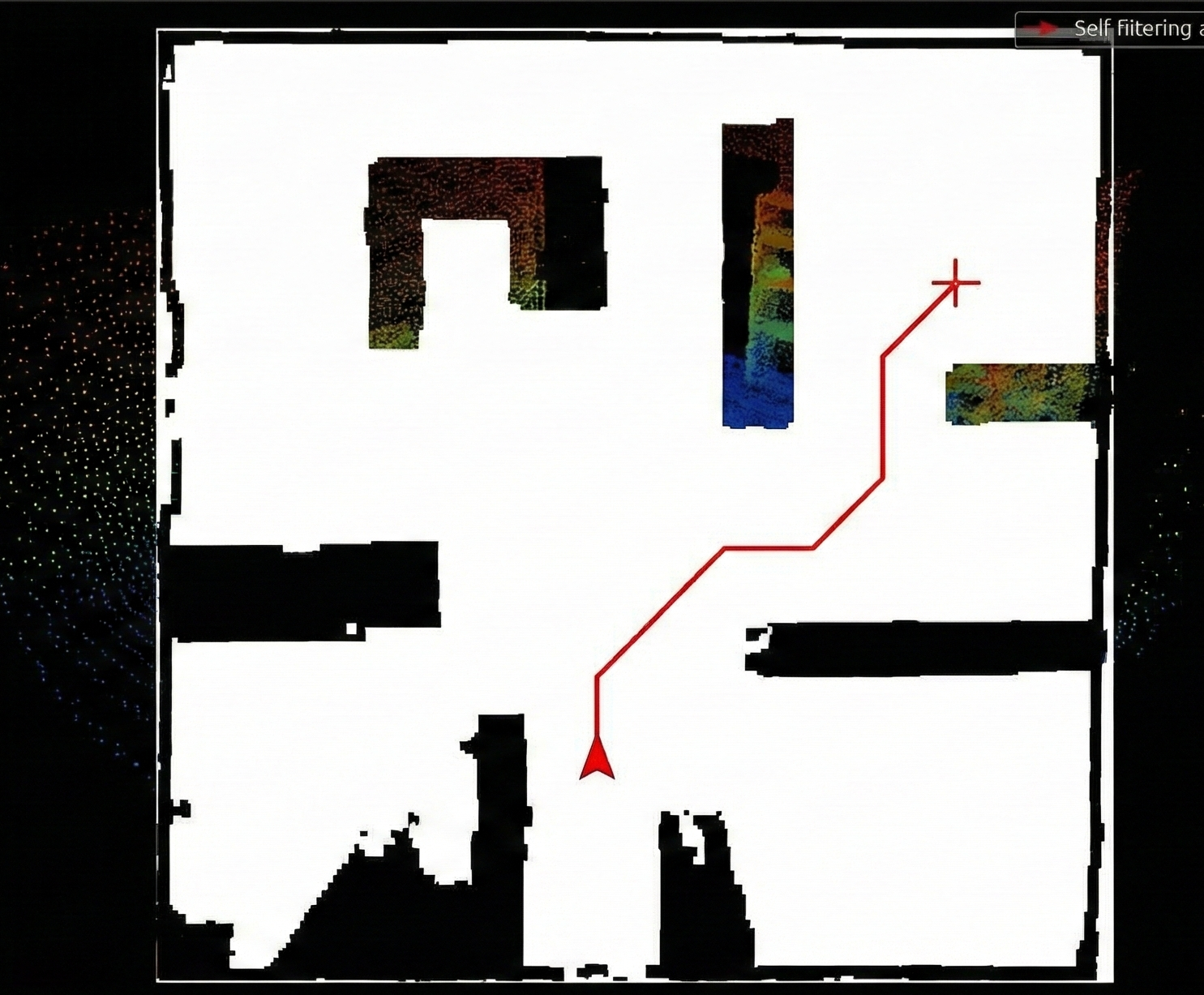

Perception & Fusion

Combines slow semantic understanding (VLM) with fast geometric tracking (ArUco) to maintain real-time responsiveness.

.png)

src: realsense_receive_rgb_min.py

Vision Language Model

SEMANTICAnswers "Where is the shampoo?" providing bounding boxes for initialization.

ArUco Tracker

GEOMETRICHigh-speed tracking of the hand marker for closed-loop control.

.png)